- Your cart is empty

- Continue Shopping

Textile Recycling: A Hope For Future

From handloom to automated machines, from wearing only cotton-based clothes to wearing widely blended products, textiles have always been something new to amaze us and motivate us to do better and better. In terms of production or in terms of consumption or in terms of utilization, the size of the market is increasing massively day by day.

If we talk about the textile industry of India, which is more than 5000 years old, has undergone significant developments starting from its modest beginnings as handlooms in villages to large-scale modern-day textile mills. From the era of ‘Cholas’, ‘Seljuks’, and ‘Safavids’ till now, Indian Textile Industry has come a long way.

The Indian textile industry is aiming to export products worth $40 to $100 billion within 2027. The technical textiles market for automotive textiles is projected to increase to US$ 3.7 billion by 2027, from US$ 2.4 billion in 2020. Similarly, the industrial textiles market is likely to increase at an 8% CAGR from US$ 2 billion in 2020 to US$ 3.3 billion in 2027. The overall Indian textiles market is expected to be worth more than US$ 209 billion by 2029.

The Indian textile and apparel market size is estimated around $165 Bn in 2022, with the domestic market constituting $125 Bn and exports contributing $40 Bn.

The market size of the industry is projected to grow at a 10% CAGR to reach $350 Bn by 2030. The global textile market size was valued at USD 1,695.13 billion in 2022 and is anticipated to grow at a compound annual growth rate (CAGR) of 7.6% in terms of revenue from 2023 to 2030.

Recycling- Importance and Area of Growth:

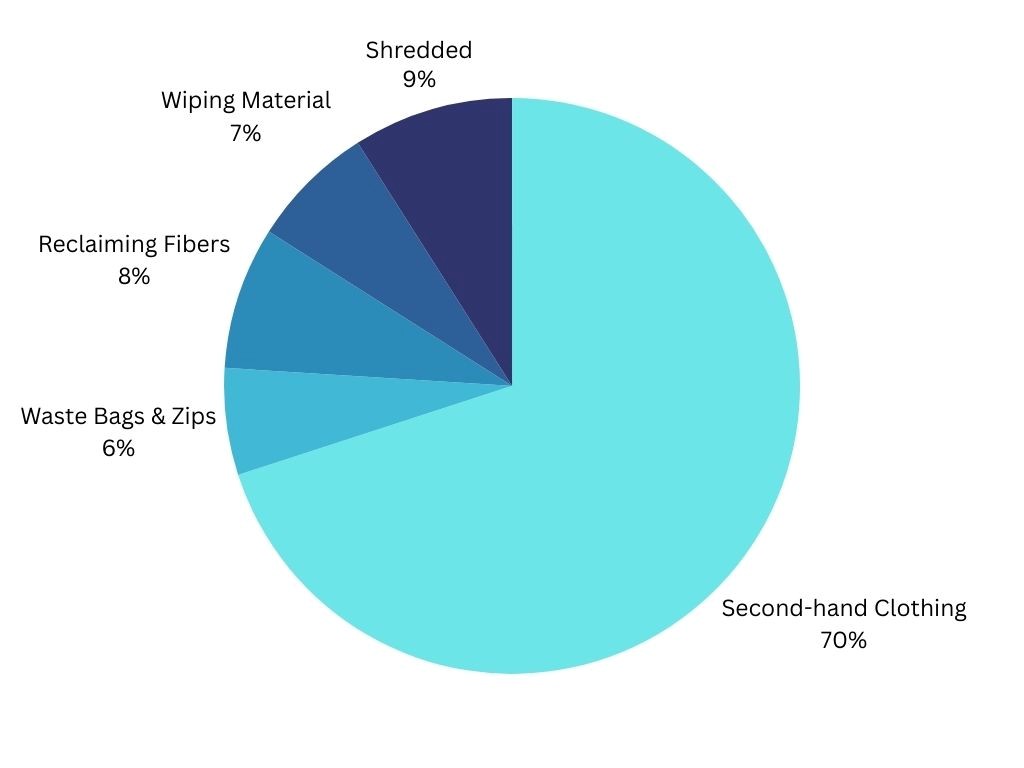

We are way ahead in terms of growth but with all of this, the major challenge we are facing is textile waste. It is costing the future to be ahead and to be more advanced with the technologies in the textile sector it should also be considered that more than one million tons of textiles are condemned every year. The average lifetime of a garment is estimated to be three years. After the period, they are thrown away as old clothes. In Household garbage, textiles make about 3 percent by weight. All this thrown clothing has the potential for recycling and reuse. 80 percent of the textiles that are thrown away can be recycled and used again. Out of all the old clothing,

70 % is used as second-hand clothing, 6% is waste bags and zips, 8% is used for reclaiming fibers and making recycled products, 7% is used as wiping material and the remaining 9% is shredded and used as stuffing. It is a surprising fact that over 70 percent of the world’s population uses second-hand clothing. Raw materials acquired out of recycled fabrics cost less; making it an attractive feature for manufacturers.

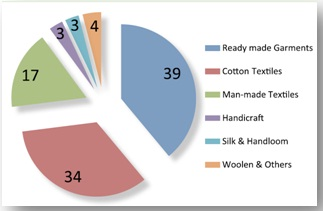

The domestic apparel & textile industry in India contributes approx. 2.3 % to the country’s GDP, 13% to industrial production, and 12% to exports. India has a 4% share of the global manufacturing in textiles and apparel.

India is one of the largest producers of cotton and jute in the world. India is also the 2nd largest producer of silk in the world and 95% of the world’s hand-woven fabric comes from India. Total textile exports are expected to reach $65 Bn by FY26 and are expected to grow at 10% CAGR from 2019-20 to reach $190 Bn by 2025-26. India has also become the second-largest manufacturer of PPE in the world, whose global market worth is expected to be over $92.5 Bn by 2025, up from $52.7 Bn in 2019. India is set to achieve $250 Bn textiles production and $100 Bn exports by 2030. India holds a 4% share of the global trade in textiles and apparel. The share of Textiles and apparel in the overall export basket of India was 10.33% during 2021-22.

There have been many technological advances in the textile industry in past centuries, some of which have radically and permanently changed how people produce and use garments. Many of these technological advances date back to the Industrial Revolution, although others are much more recent. There is one invention that undoubtedly made the biggest difference in how fabrics are produced. That invention is the power loom. One of the latest technological advances used in the garment industry is nanotechnology. With the advancement in technology, every single scenario has been changed from production to styling, from expensive to cheaper, from lesser available to widely available, and whatnot.

All clothing has a useful second life. The collected garments are sorted and graded as natural, synthetic, and blended fabrics. Fibers from the old fabrics are reclaimed and are used for making new garments. Threads from the fabric are pulled out and used for re-weaving new garments or blankets. Both natural and synthetic fibers can be recycled this way. Incoming textiles are graded into type and color. Initially, the material is shredded into fibers called shoddy. Later based on the end use, other fibers are blended with shoddy. The blended mixture is carded and spun for weaving or knitting.

Another way is that the garment is shredded for fillers in car insulation, roofing felts, loudspeaker cones, furniture padding, panel linings, and many other uses. Woolen garments are sent to other firms that make fiber reclamation to make yarn and fabric. Cotton clothes are recycled and used for paper manufacture, automotive, mining industries, and various other uses.

In theory, textile-to-textile recycling has a lot of potential to help create a more sustainable future for the fashion, textile, and apparel industry. On the ground, the processes needed to make it happen are extremely complex.

There is a company called SuperCircle that exists to help make textile-to-textile recycling a working reality. The tech and reverse logistics company does this by connecting the fashion and retail sector to post-consumer textile waste and recycling infrastructure, filling a crucial logistical gap in the circular textile economy.

It is built to fill this gap and make circularity a reality today. The biggest barrier for SuperCircle is the education gap within the retail industry around what true circularity is. The biggest challenge for fiber-to-fiber recycling (especially with post-consumer garments) is the cultivation of clean material feeds. It requires the identification, collection, sortation, and aggregation of garments into feeds containing the same fibers, such as cotton with cotton, wool with wool, etc.

The two most important steps that a brand can take towards textile-to-textile recycling are:

● Designing products that can be recycled. This includes thinking through and mapping the material composition, and garment construction, and making decisions upfront that make recycling feasible

● Incorporating a takeback program from the outset. Textiles, footwear, and accessories aren’t municipally recyclable. Brands need to launch take-back programs to recapture their garments. A garment can be 100% recyclable if there isn’t a viable recycling channel.

Recycled polyester is a prime choice for active individuals who want high-performance fabrics. It is known for its moisture-wicking properties and its ability to withstand years of frequent wear and washings. All this without losing its shape, color, or soft feel. After the introduction of polyester in the textile industry, it has made a significant space in the industry with the highest market share of any fiber at 54%. Today, the average percentage of recycled polyester in textiles is 15 percent, and initiatives such as Textile Exchange’s 2025 Recycled Polyester Challenge are driving the apparel industry to boost that number to 45 percent by 2025. This is due to the competitively low price of fossil-based polyester. While it uses substantially less CO2 and avoids the need for more crude oil extraction, you can’t recycle recycled polyester. This is in slight conflict with the ideal lifecycle of a garment — reuse, then repair, then resale, and then finally recycling.

Methods of Recycling:

Textiles for recycling are generated from two primary sources. These sources include:

1. Post-consumer, including garments, vehicle upholstery, household items, and others.

2. Pre-consumer, including scrap created as a by-product from yarn and fabric manufacture, as well as post-industrial scrap textiles from other industries.

Recycling Methods:

1. Chemical Recycling

Chemical fiber-to-fiber recycling requires pure fractions, making the development of effective separation processes a crucial factor in the advancement of textile recycling. It encompasses various processes where changes are made on the molecular level to textile fibers through chemical treatments to create recycled fibers.

Tyton Biosciences (US) uses water as a solvent to produce cellulosic pulp and polyester monomers from cotton polyester blended fabrics which are further used to make polyester or other materials. Worn Again Technologies takes non-reusable textiles and then cleans, extracts, separates, and regenerates virgin-quality polyester and cellulose from them, which is used to make rayon. Ambercycle’s technology produces PET polymers from blended textile waste that can be spun into polyester yarn.

2. Mechanical Recycling

Textiles may also be recycled mechanically, where they are mechanically defibrated into fibers that can be spun into yarns for textile production, either with or without the addition of virgin fibers. Here the fibre composition of the textile waste becomes the same as the recycled fibre. However, the mechanical recycling of most textile materials often results in fibers of lower quality, leading to a process known as downcycling. However, a higher level of quality can be achieved by blending recycled shorter fibers with virgin fibers. They are mostly CO2 emission-friendly, with a 60 to 90 percent reduction potential across all fiber types on spun fiber levels. Companies such as Purfi and Recover are among those exploring advanced mechanical recycling techniques.

3. Thermo-Mechanical Recycling

Thermo-mechanical recycling uses a combination of heat and pressure to melt synthetic textiles like polyester and polyamide and recover polymers. However, this technology does not apply to natural fibers such as cotton or wool or MMCF (man-made cellulosic fibers) like viscose. It is notable for its relatively low energy consumption and the potential to minimize quality degradation compared to many other mechanical recycling methods. So far, the technology has mostly been proven effective for non-textile waste.

4. Thermo-Chemical Recycling

Thermo-chemical recycling is an open-loop technology that uses gasification to produce syngas through the partial oxidation reaction of polymers. This approach is compatible with all types of fibers. However, it is essential to note that this technology is not a closed-loop application for textiles. This technology aims to tackle textile waste comprehensively without restricting fiber composition. Beyond textile waste, this recycling method can potentially address the residual waste from other recycling processes (such as the non-cotton share of the MMCF process).

5. Bio Recycling

Textile waste recycling can be achieved through a bioprocess incorporating enzymatic hydrolysis with ultrasound pre-treatment to transform composite materials into bio-products. The polyester component can be re-spun into reusable yarn, while the generated cellulosic powder can undergo further processing to produce soluble glucose. The Green Machine, developed by the Hong Kong Research Institute of Textiles and Apparel (HKRITA), is a viable commercial solution to separate cotton and polyester blended textile.

Types of recycling technologies:

Thermal recycling technology: Thermal recycling is intended to recover heat energy generated from the incineration of fiber wastes as thermal or electrical energy. Material Recycling Technology: Material recycling recovers polymers from fibers and at present, the idea of transforming polyethylene terephthalate (PET) into fibers is most economical and widely used for practical purposes.

Chemical recycling technology: Chemical recycling recovers monomers from waste fibers by polymer decomposition. Impurities can be easily removed from recovered monomers, so their quality will be exactly equal to virgin monomers.

Benefits of textile recycling:

Textile and clothing recycling can give old clothes, linens, and other textiles a second life. The recovery of textiles and clothing for recycling provides both environmental and economic benefits. It avoids many polluting and energy-intensive processes that are used to make textiles from fresh materials.

Focus for the future- A shift toward recycled textiles

From 2025, used clothing and other textiles will be collected separately throughout Europe to facilitate reuse and high-quality recycling. Activities for the development of new fibers, chemical auxiliaries, and colorants that are more suitable for recycling are on the way. New regulations for the textile industry have been introduced in several countries that favor the use of recycled materials. On March 30, 2022, the European Commission published the EU Strategy for Sustainable and Circular Textiles which outlines the EU’s action plan to achieve better sustainability and regulation within the textile industry. The European Commission’s goal for 2030 is to encourage consumers to invest in high-quality products rather than “fast fashion”, and to ensure all textile products are durable, whether they are recycled materials or not. The EU’s strategy includes regulating overproduction, reducing the release of microplastics during production, and utilizing EU Extended Producer Responsibility to ensure producers are acting sustainably.

increased to achieve better sustainability in the textile industry. Inditex and Bill Gates’s Breakthrough Energy Ventures invested in the start-up recycling company Circ in July 2022, which has patented new technologies to re-engineer used fibers. In July 2021, H&M and Adidas invested in the chemical recycling company Infinite Fiber Company (IFC) which produces a re-engineered fiber that is similar to cotton and is biodegradable. Goldman Sachs led an investment in mechanically recycled cotton company Recover Textile Systems in June 2022.

Many luxury fashion brands are publicly displaying their investment in sustainability approaches, with a common goal to shift towards circular systems and utilizing re-engineered and/or biodegradable materials in their collections.

Author

~Chetanya Changia

Having a keen interest in the fashion and apparel industry, Graduated in textiles.

He has a futuristic approach and believes in creating something sustainable. He has experience in retail and sales with good knowledge of maintaining public relations. He has done projects in technical textiles and is further working to build a healthy environment.