- Your cart is empty

- Continue Shopping

Evolution of Manufacturing Practices in Sustainability

Green Building

Green building is a concept that aims to minimize both embodied and operational carbon within a structure. This is achieved by incorporating practices such as using renewable, recyclable, and reusable materials for construction. Additionally, strategic location selection plays a key role in overall cost reduction, considering factors such as proximity to highways, lower wages, access to skilled labor, and availability of vendors and customers. The green building concept extends to planning the construction of manufacturing units, emphasizing the utilization of natural light, and natural ventilation (informed by Windrose diagrams), and implementing features like effluent treatment plans and sewage treatment plants to maximize energy and waste efficiency.

Green business (GB) maintains the sustainability of eco-friendly, financial, and social targets within the production area and tries to form a strong foundation for all three pillars of sustainability in the business process (Dominis, Sharpe, & Fernandez, n.d.)

The global commitment to combat climate change, as outlined in the Paris Agreement, emphasizes the need for substantial reductions in greenhouse gas (GHG) emissions. Various industries, including the garment and textile sector, have responded by setting ambitious targets to align with the Paris Agreement’s objectives. (Dominis, Sharpe, & Fernandez, n.d.) In 2018, stakeholders in the garment industry established the United Nations Framework Convention on Climate Change (UNFCCC) Fashion Industry Charter for Climate Action, committing to significant emission reductions and net-zero targets by 2030 and 2050, respectively. (Dominis, Sharpe, & Fernandez, n.d.)

Annual growth rate of production in the manufacturing industry in India from financial year 2013 to 2022

The manufacturing industry in India has emerged as a fast-growing sector owing to the rapidly increasing population in the country. (Rathore, 2023) Investments in the sector have been on the rise and initiatives like ‘Make in India’ are aiming to turn the South Asian country into a global manufacturing hub. (Rathore, 2023) The annual growth rate of production in the manufacturing industry was 11.4 percent during fiscal year 2022. (Rathore, 2023)

- Value added in the Manufacturing market is projected to amount to US$244.50bn in 2023.

- A compound annual growth rate of 8.36% is expected (CAGR 2023–2028).

- Output in the Manufacturing market is projected to amount to US$1,313.00bn in 2023.

- A compound annual growth rate of 4.36% is expected (CAGR 2023–2028).

- The number of enterprises in the Manufacturing market is projected to amount to 240.40k in 2023.

- A compound annual growth rate of 1.73% is expected (CAGR 2023–2028). (Rathore, 2023)

Understanding the Environmental Impact of the Building Industry: Embodied Carbon vs Operational Carbon

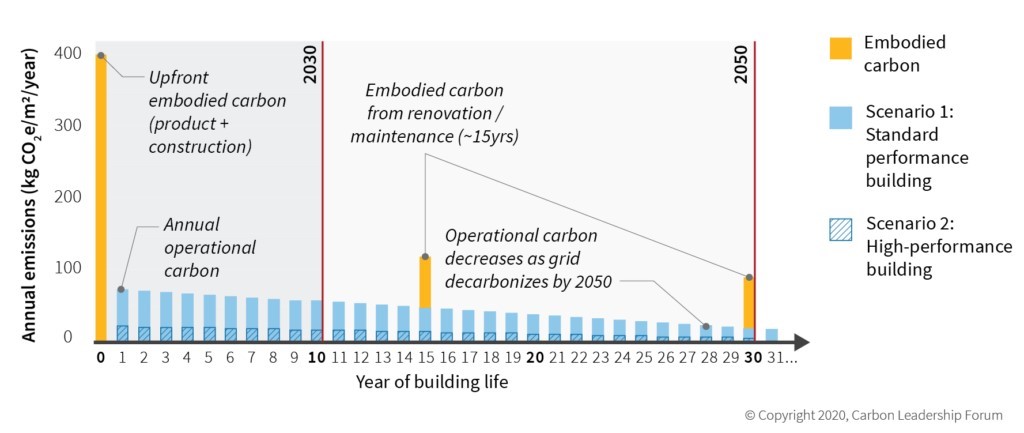

In the construction industry, embodied carbon pertains to the greenhouse gas emissions generated during the manufacturing, transportation, installation, maintenance, and disposal of building materials. In contrast, operational carbon denotes the greenhouse gas emissions resulting from the energy consumption of a building. (Jarrett, 2023)

To assess greenhouse gas emissions and their impact on climate change, scientists employ a method known as life cycle assessment (LCA) to monitor emissions throughout the entire life cycle of a product or process. These emissions are then translated into metrics reflecting their potential environmental effects. One such metric is global warming potential (GWP), measured in kilograms of CO2 equivalent (kg CO2e), commonly referred to as a carbon footprint. (Jarrett, 2023)

Embodied vs. Operational Carbon

While operational carbon diminishes with grid decarbonization, embodied carbon, incurred before use, remains a critical factor. Managing embodied carbon is pivotal for achieving net-zero targets by 2050.

Life-Cycle Assessment (LCA)

LCA assesses the environmental impact of construction projects, analyzing them from inception to completion. Evaluates the origin and production of materials like wood, concrete, and steel.

- Building (Embodied Carbon): Examines energy use, waste, and emissions during the construction process.

- Use (Operational Carbon): Considers ongoing energy usage during the building’s operational phase.

- End of Life: Addresses the disposal or recycling of the building once it’s no longer in use

The objective of a Life Cycle Assessment (LCA) is to construct buildings in a manner that minimizes their adverse impact on the environment, aligning with our carbon reduction targets. Historically, measuring and monitoring embodied carbon posed challenges. (Jarrett, 2023)

Global share of building and construction final energy and emission 2021.

More progress is required on the global adoption of mandatory building energy codes and for existing codes to align to zero emissions.

- Since 2020, there has been little progress on national building energy codes in countries which are yet to adopt them

- In 2021, 79/196 (40%) of countries had building energy codes which are either mandatory for at least part of the building stock or have a voluntary component. Yet, only 26% of countries had mandatory codes for the entire building sector.

3. In 2021, the number of green building certifications increased by 19% across the world compared to 2020. (program, 2022)

The ambition to act on buildings’ emissions has increased but must be matched by action in policy, regulation, and continued investment.

- In 2021, 158 countries mentioned buildings in their Nationally Determined Contributions (NDCs), of which 118 referred to energy efficiency as a part of their emissions reduction strategy. However, the ambition of NDCs must be matched by the increased adoption of building energy codes.

- Just under 20% of the world’s population lives in countries whose NDC has no or limited references to buildings. (program, 2022)

The Urgency of Embracing Green Building Principles Today

Despite increased investment in energy efficiency and reduced energy intensity, a recent report reveals that the building and construction sector has experienced a rebound in energy consumption and CO2 emissions following the COVID-19 pandemic, reaching an all-time high. (SHEIKH, 2022)

Released during COP27 in Egypt, the 2022 Global Status Report for Buildings and Construction indicates that the sector contributed to over 34% of energy demand and approximately 37% of energy and process-related CO2 emissions in 2021. (SHEIKH, 2022)

Operational energy-related CO2 emissions surpassed ten gigatonnes of CO2 equivalent, exceeding 2020 levels by 5% percent and surpassing the pre-pandemic peak in 2019 by 2% percent. The report from the Global Alliance for Buildings and Construction (GlobalABC) highlights that this trend is widening the gap between the sector’s climate performance and the 2050 decarbonization pathway. (SHEIKH, 2022)

Notably, approximately 30% of global carbon emissions are linked to the building sector, emphasizing the need for eco-friendly practices in the manufacturing of construction materials and beyond. (Jarrett, 2023)

Construction companies can contribute to achieving our 2050 carbon reduction goals by employing fewer materials overall and substituting high-carbon materials with those emitting lower levels. (Jarrett, 2023)

Successful Green Building Concept Implementation

Brandix Apparel Ltd

- Achieved milestones like the world’s first Net Zero Carbon Apparel Manufacturing facility in 2019.

- Commitment to being Net Zero Carbon in all Sri Lankan facilities by 2023 and all Indian facilities by 2025. (Brandix, 2023)

Aquarelle India Private Limited

1.A garment firm based in Samudra, Karnataka, owned by CIEL Textile.

2. Aquarelle Samudra factory was honored with LEED Platinum Certification, a rarity among Indian garment manufacturers.

3. Recognized by the US Green Building Council (USGBC) for outstanding efforts in energy and environmental design

4. Excelled in water efficiency, energy & atmosphere, innovation, and regional priority credits.

5. Implementation of eco-friendly methodologies in operations and design, securing the LEED Platinum Certificate. (Desk, 2020)

Here are key strategies to achieve the green building concept in manufacturing:

1. PESTAL Analysis

2. Location Analysis

3. Bylaws Compliance

4. Energy Efficiency Measures

5. Sustainable Materials

6. Waste Reduction and Recycling

7. Water Conservation

8. Employee Education and Engagement 9. Continuous Improvement

By adopting these strategies, manufacturing industries contribute to global sustainability goals, gaining a competitive edge in an eco-aware market. As the industry shifts towards environmentally conscious consumerism, embracing green building concepts becomes a strategic necessity and investment in a greener, more resilient future.

Reducing carbon emissions necessitates addressing embodied carbon, encompassing the entire building structure and the materials used. By integrating green building concepts, the embodied carbon can be gradually reduced. Establishing a building based on green principles enhances overall energy and waste efficiency. This results in increased waste and energy management levels by minimizing consumption, thereby indirectly managing operational carbon.

Author

Shreya Gupta, fueled by a deep-seated passion for the fashion industry. My specialization encompasses Apparel Production and Fashion Retail, emphasizing sustainability, quality analysis, and proficient utilization of Computer-Aided Design tools like Tuka Marker/Design and AutoCAD 3D. Throughout my professional journey, I have amassed invaluable experiences during internships with reputable fashion entities, actively contributing to digitization and streamlining initiatives. Moreover, my portfolio includes research-based projects, showcasing a comprehensive understanding of merchandising and the intricacies of the production process.